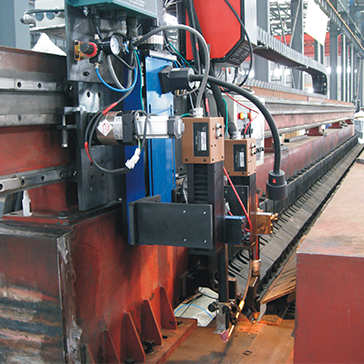

Plate Seamer

Equipment designed for plate welding in high production. Commonly used for railroad carts or panels manufacturing.

It has an entrance table, a pneumatic grip system, a copper backing for the welding, a gantry with a welding torch and a discharge table. After applying the welding, the plates are joined together by both sides without needing to turn. It works for TIG, MIG or subarc processes.

Weldtech Positioning offers these systems integrated and installed with all the equipment required. They are custom made in terms of thickness and length.

Contact Us

Please let us know any concern, requirement, project, comment or complaint.

Our policy is to answer your request within 24 hours.

If you are interested in a specific product or project, please send us all the information available about your pieces or processes in order to bring you the best answer in less time.